Bioplastics Solutions and A New Alternative

What are Bioplastic Solutions?

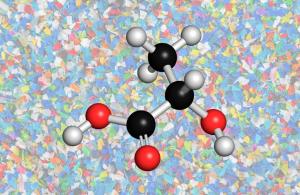

Bioplastics are a diverse group of materials derived from biological sources. Unlike traditional plastics synthesized from fossil fuels, bioplastics can be composted or biodegraded under specific conditions. This biodegradability offers a significant environmental advantage, reducing plastic waste accumulating in landfills and oceans.

However, there are key differences between bioplastics and traditional plastics:

Source Material

Bioplastics come from renewable resources like corn starch, sugarcane, or cellulose, while traditional plastics rely on non-renewable petroleum.

Biodegradability

Some bioplastics are biodegradable under specific composting conditions, while others may only partially degrade or require industrial composting facilities. Traditional plastics are not biodegradable.

Challenges and Limitations of Bioplastics

While bioplastics offer a promising alternative, they face several challenges:

Cost of Production: Bioplastics are often more expensive than traditional plastics due to lower production volumes and complex processing.

Performance Limitations: Some bioplastics may not match traditional plastics' thermal and mechanical properties, limiting their applications.

Biodegradability Requirements: Not all bioplastics are created equal. Some require specific industrial composting facilities for biodegradation, which may not be widely available.

Contamination Risks: An entire batch of Bioplastics can be contaminated when recycled with traditional plastics, rendering them unusable.

Recycling Infrastructure Limitations: Recycling infrastructure for bioplastics is still under development in many regions.

Extended Producer Responsibility (EPR) and Bioplastics

It's important to note that Extended Producer Responsibility (EPR) policies are playing an increasingly important role in plastic waste management. EPR places the responsibility for the end-of-life management of a product on the producer. This can incentivize producers to develop more sustainable products, including bioplastics, and improve collection and recycling infrastructure.

A New Alternative: Pristine® Biodegradable Plastic Additive

The limitations of bioplastics highlight the need for innovative alternatives. Pristine® presents a new approach with its biodegradable plastic additive. It is a developed, independently tested, efficient solution addressing the most common problems with other biodegradable plastics.

Pristine® plastic additive offers a better alternative because:

It turns traditional plastics into biodegradable materials. Pristine® is formulated for compatibility with the world’s most common non-bio-based plastics, including PP, PVC, PET, HDPE, LDPE, EPDL, nylons, styrenes, and olefins. No need to retool or produce a bespoke bioplastic material; Pristine® works with existing materials and production facilities.

It allows plastics to biodegrade in numerous environments. Pristine® has been tested by independent third parties using ASTM testing methods, and it is recognized and accepted worldwide. Pristine® enhances the biodegradation rate of traditional plastics, allowing them to biodegrade and compost in landfills and marine environments. It ensures that, if recycling is not an option, plastic materials no longer remain in the environment indefinitely.

It does not hinder performance. Plastic materials treated with Pristine® lose none of their original qualities. They remain durable, versatile, easy to process, and cost-efficient to produce.

Pristine®’s mission is to contribute to sustainability and make a positive difference for our planet and its future.

Plastic production and our economic future may depend on it.

Info. at Pristine LLC

Pristine LLC

+1 208-870-0965

info@pristine.llc

Visit us on social media:

Facebook

LinkedIn

EIN Presswire does not exercise editorial control over third-party content provided, uploaded, published, or distributed by users of EIN Presswire. We are a distributor, not a publisher, of 3rd party content. Such content may contain the views, opinions, statements, offers, and other material of the respective users, suppliers, participants, or authors.